1.SVOLT as a company

General

SVOLT is a global high-tech company based in China that develops and produces high-quality lithium-ion batteries and battery systems for electric vehicles as well as energy storage systems.

Founded in 2012 as a business unit of Chinese automaker Great Wall Motor, SVOLT now operates as an independent automotive supplier under SVOLT Energy Technology Company Limited.

The Chinese high-tech company is headquartered in Jintan District, Changzhou, Jiangsu Province in China. Chairman and CEO is Mr. Hongxin Yang.

Headquarters of the European subsidiary SVOLT Energy Technology (Europe) GmbH is Frankfurt am Main since 2019. President SVOLT Europe & Vice President SVOLT Energy Technology is Mr. Kai-Uwe Wollenhaupt.

Worldwide, SVOLT offers its customers an extensive one-stop product portfolio. This includes battery cells and their cell chemistry, modules and high-voltage storage (battery packs) as well as battery management systems (BMS).

In addition to solutions that meet global market standards, SVOLT works intensively on the development of new technologies and the continuous enhancement of existing ones: from cell chemistry and complete battery packs to cloud-based software solutions.

SVOLT is a sister company of Great Wall Motor (GWM) and is part of Baoding Great Wall Holding, which is also a shareholder of Great Wall Motor. SVOLT is among the top 10 global manufacturers of automotive batteries.

SVOLT employs around 15,000 people worldwide (Q1 2023). With two large R&D centers in Baoding and Wuxi, both in China, and eight other R&D hubs, SVOLT employs around 3,000 people in R&D alone at the beginning of 2022.

SVOLT is convinced: Hardly any measure will make a greater contribution to climate protection around the world than the widespread spread of electromobility. The affordability and thus mass suitability of electromobility stands and falls with the performance of the energy storage systems used in electric vehicles. Making electromobility fit for the future - that is SVOLT's mission. That's why safety, cost-effectiveness, sustainability and energy density are the focus of our work around the world. Innovation and systemic expertise drive progress for SVOLT, which is why the company motto is "Driven by Innovation."

Customers

SVOLT is currently in contact and exchange with all European OEMs. The first customer projects have already been agreed with European customers and are currently in the implementation phase.

At the end of July 2021, SVOLT announced several orders from Chinese and international automakers, including Stellantis, Great Wall Motor, Geely Automobile, Dongfeng Motor, SF Motors, ENOVATE, Leap Motor and Hozon Auto.

SVOLT has deep systemic knowledge in battery systems and management, as well as extensive expertise in vehicle integration. SVOLT is thus able to offer its customers customized solutions on battery cell, module and high-voltage storage (pack) level as well as corresponding software.

By taking a holistic view of vehicle architecture and battery system, SVOLT helps OEMs create safer, highly functional, durable and cost-effective products that also focus on the needs and expectations of end customers.

Research + Development

In addition to solutions that meet global market standards, SVOLT works intensively on the development of new technologies and the continuous further development of existing ones - from cell chemistry to the complete battery pack.

Among other things, SVOLT is the first company to have succeeded in stabilizing a high nickel cell chemistry without cobalt and bringing it to industrial production readiness. The first vehicles with this technology have been registered since 2021.

SVOLT also employs an active research and development team working on solid-state batteries.

For example, SVOLT made decisive progress in the development of solid-state batteries. The company produced its first batch of 20Ah cells with sulfide-based solid-state electrolyte in mid-2022. These solid-state cells are considered the next step in the development of advanced battery technology. SVOLT is the first battery manufacturer in China to demonstrate the production of this type of solid state cell.

SVOLT is also developing battery management systems that directly control the high-voltage storage in the pack, as well as software solutions for cloud-based service applications.

Expansion Europe

Germany lies at the heart of the automotive industry in Europe. SVOLT wants to be actively close to its customers so that it can also develop as a company together with its customers. In order to keep the CO2 footprint as low as possible, SVOLT pursues a local-for-local approach worldwide. The aim here is to establish local supply chains and enable them to provide the materials required - where available. By doing so, SVOLT reduces potential negative impacts on its supply chain due to delays and unforeseen incidents. It also helps reduce delivery routes and times to European customers, which in turn has a positive impact on the sustainability of electric vehicles.

Germany is a modern industrial, logistics and innovation location and thus offers SVOLT the opportunity to acquire highly qualified employees. The excellent education of the technical experts, especially from the fields of mechanical engineering and electrochemistry, have convinced SVOLT. The transformation of the labor market towards new mobility topics will release highly qualified workers. These will find a connection at SVOLT. Being close to the market and the experts allows SVOLT to grow faster as a company.

SVOLT opened its first cell factory in November 2019 in Jintan, China, 3 hours from Shanghai. European plants are to be built in Saarland. In addition, further plants are to be added globally. Module and pack plants are being built, where the battery cells are assembled into finished battery modules and packs.

SVOLT strives to offer its state-of-the-art technologies and innovations in all geographical zones. This means that not only fractions of technology will be moved to Europe, as is often seen when expanding from Europe to China.

Due to existing market conditions, SVOLT's initial focus in Europe will be on subsystems such as battery cells and modules and their control systems, in contrast to the Asia-Pacific region.

In order to keep the CO2 footprint as low as possible, SVOLT pursues a local-for-local approach. The aim here is to establish and enable local supply chains to provide the materials required - where available. This applies to the cell factory as well as the module and pack production in Saarland.

However, since the module and pack factory in Heusweiler will be commissioned before the first cell plant is built, production of SVOLT's modules and battery packs will initially start with battery cells from other SVOLT factories.

As a global company, SVOLT also plans to launch extensive R&D activities in Europe - although the thematic focus has not yet been finalized. Customer-related development projects are also to be established in Europe. In principle, SVOLT aims to give all its sites the best possible capabilities.

2.SVOLT as an employer

SVOLT was founded in 2012 as a division of the Chinese automotive manufacturer Great Wall Motor and has been an independent automotive supplier since 2018. The experienced automotive manager Kai-Uwe Wollenhaupt is responsible for the European activities as Managing Director of the German-based SVOLT Energy Technology (Europe) GmbH.

SVOLT's headquarters are located in Jintan District, Changzhou, Jiangsu Province in China. The headquarters of the European subsidiary SVOLT Energy Technology (Europe) GmbH is Frankfurt am Main.

SVOLT's planned production facilities in Germany will be among the most modern and advanced of their kind in the world. Labor law requirements such as occupational safety and employee protection have the highest priority already in the planning phase. It is important to SVOLT that its employees not only feel comfortable at the site, but that they are enthusiastic about their work. For this reason, SVOLT will also adhere to all customary, nationally and regionally specific standards and specifications.

SVOLT will enrich the labor market with future-proof modern jobs. Here, the company is working closely with all key local partners. Training and qualification will have a high priority at SVOLT. This is the only way to ensure the great demand for committed and qualified employees in a high-tech industry. In view of the shortage of skilled workers in Germany and Europe, it is important to SVOLT to invest in training and qualification and thus in the skilled workers of tomorrow. Therefore, SVOLT also plans to provide training from the start of production. SVOLT's human resources management will pay particular attention to a balanced mix of age groups, genders and nationalities here. SVOLT will of course also fulfill its social obligation to employ severely disabled persons.

The search for employees has already begun. The current job advertisements can be found on the following website:https://SVOLT.jobs.personio.de/.

SVOLT's central concern is the promotion of electromobility - also within its own organization. In addition, SVOLT is currently looking into further electromobility offers for future employees.

3.Battery Production

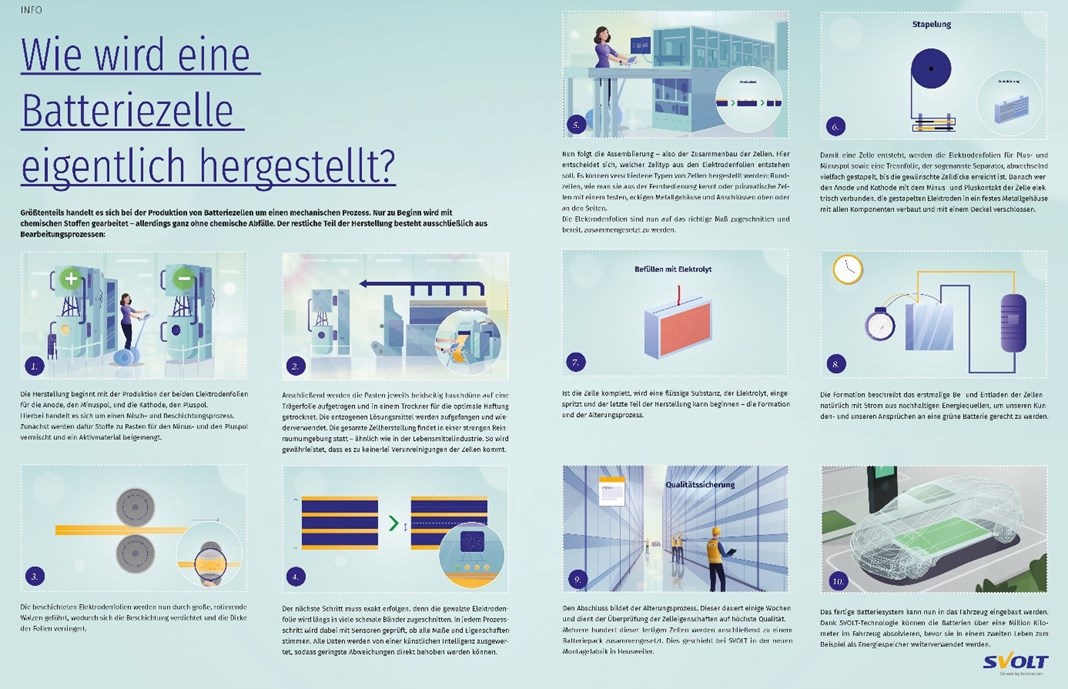

A battery for electric cars, like smartphone batteries, consists of electrodes (anode and cathode), a separator that separates the electrodes from each other, and the ion-conducting electrolyte in between.

In the first step, different substances are mixed to form pastes for the positive (cathode) and negative (anode) poles. These two pastes, which have a consistency like a fairly liquid, homogeneous dough, are a mixture of liquid (solvent) and solid substances (in powder form, like flour). The active material is also mixed into the cathode - e.g. lithium, manganese or cobalt, depending on the cell type.

Coating in the next process step is highly demanding: Here, the pastes are applied extremely thinly to a carrier foil made of copper or aluminum - from both sides. The resulting electrode foil is fed directly into the dryer so that the solvent can be removed from the paste and it adheres to the foil as a dry layer. The solvent is collected and reused.

Next, the dried electrode foil is run through rotating rollers to increase the density of the coating and correct variations in coating thickness. Next, the rolled electrode foil is divided longitudinally into several, smaller strips.

After being dried again, the electrode foils are cut to the correct size. In each process step, sensors are used to check whether all dimensions and properties are correct. All data is evaluated by an artificial intelligence system so that the slightest deviations can be corrected immediately.

In order for a cell to be created, the electrode foils are now stacked or wound in a repeating cycle of anode, separator, cathode, separator, and so on. The final step in electrode fabrication is to make the electrical connection of the cathode and anode.

Now all the components of the cell (electrode winding or stack, housing, lid, gasket, insulation and safety valve) are assembled. The lid is then welded to the housing. In the next step, the electrolyte is injected into the cell.

The finished cells are loaded and unloaded for the first time. This process takes up to 24 hours. The cells are then stored for several weeks to identify short circuits and check the cell properties.

Several of these cells are then assembled into battery modules and connected together. Installed electronics monitor the individual cells.

Several battery modules form the battery system (high-voltage storage / battery pack), which is installed in the vehicle as a closed overall system. In the battery system, electronics regulate the charging and discharging processes of the modules (and thus of the cells). In addition, the capacity, state of charge, battery voltage and temperature can be monitored. A cooling and heating system ensures consistent performance and longevity of the cells.

An explanatory video on battery production can be found on YouTube: https://www.youtube.com/watch?v=h9E3vy56tgg

The raw materials required depend on the type of battery system and its cell chemistry; however, all SVOLT batteries rely on lithium as the basic material. The main components of SVOLT batteries are manganese, nickel, iron phosphate and graphite. In some cases, cobalt is also included, insofar as SVOLT's customers desire these battery forms. In addition, SVOLT also offers cobalt-free cell chemistries to make electromobility even more sustainable. Both SVOLT's production and supply chain are set up according to international standards and are regularly audited.

According to statements by the German Federal Ministry for the Environment, Nature Conservation, Building and Nuclear Safety, "there are by far sufficient resources of the relevant raw materials lithium, cobalt, graphite and nickel, even for a large-scale switch to electric cars on a global scale. Greater material efficiency, increased recycling and, if necessary, material substitutes can also help mitigate environmental impacts and cushion price increases."(Source: Brief information on electromobility regarding electricity and resource requirements).

As a systemic supplier, SVOLT develops and produces lithium-ion batteries optimized for the automotive sector. These include lithium iron phosphate (LFP) batteries and lithium nickel cobalt manganese (NCM) batteries, as well as novel cobalt-free batteries (NMx).

In order to make raw material production and its supply chain as transparent as possible, SVOLT has already been investing specifically in lithium mining and ore processing with Pilbara Minerals (Australia) and Tianyuan New Energy Material (China) since 2017. Both companies - like all SVOLT suppliers - are regularly audited according to international standards. This auditing forms the basis for supply capability to EU customers.

4.Solutions + Products+ Technology

General

SVOLT offers its customers a comprehensive one-stop product portfolio - including battery cells with state-of-the-art cell chemistry, modules and packs, and corresponding battery management systems.

As a systemic supplier, SVOLT develops and produces lithium-ion batteries optimized for the automotive sector. These include lithium iron phosphate (LFP) and lithium nickel cobalt manganese (NCM) batteries, as well as novel cobalt-free batteries (NMx).

Depending on customer requirements, application and vehicle design, SVOLT offers a wide range of battery cell designs in the familiar shapes (prismatic, cylindrical and pouch). These include products according to MEB and VDA standards with top terminal design as well as L-type battery cells with side terminal design.

In addition to developments for customer projects, SVOLT offers automotive standard systems (MEB, VDA) on module level as well as SVOLT-specific special solutions (Cooling Plate Integrated Module (CPIM) and Scalable Battery Systems (SBS).

SVOLT develops cost- and weight-efficient battery packs for a wide range of vehicle types and sizes. In addition to solutions that meet global market standards, SVOLT offers pack designs based on SVOLT's own module developments (CPIM and SBS). In addition, SVOLT is working on module-free solutions such as Cell-to-Pack, which are already being implemented in initial customer projects.

In the future, vehicle manufacturers will be able to analyze data from vehicles with SVOLT technology via the so-called "SVOLT Cloud Platform" and thus offer their customers additional services, e.g. intelligent battery monitoring, service and residual value analyses.

NMx

For the cobalt-free NMx battery cells, SVOLT has developed a novel cathode material that consists of 75 percent nickel and 25 percent manganese. The cathode is stabilized by doping and coating processes developed in-house. In a doping process, SVOLT introduces foreign atoms into the cathode material. As a result, NMx cells - even without cobalt - achieve higher thermal stability and overall safety than NCM811 cells (high-nickel cells). With the help of the new technology, it has also been possible to significantly improve the cycle aging as well as the calendar life of NMx cells compared to conventional NCM811 battery cells. This means that more than 2,500 charging cycles are possible.

The long service life of NMx battery cells is achieved, among other things, by an ultra-thin surface coating (nano-coating) consisting of only a few hundred atoms. It protects the surface of the cathode from side reactions with the electrolyte and prevents battery degradation. As a result, the capacity of NMx batteries, and thus their range, decreases less over time.

To further prevent the formation of micro-cracks and fractures in the active cathode material and thus the wear of the cell, SVOLT also uses a single crystal structure (NMx H) for the cathode material. Unlike polycrystalline structures, all particles here have the same crystallographic orientation. This means that all the building blocks of the cathode form a continuous, homogeneous crystal lattice that does not change even under external influences. The material expands and contracts less than polycrystalline structures whose particles are of different sizes and orientations. This prevents the formation of micro-cracks and fractures in the cathode and thus cell aging.

The high-tech company's cobalt-free NMx battery has been installed in vehicles and offered to customers/consumers since mid-2021.

With nickel-manganese cell chemistry (NMx), SVOLT is able to produce high-nickel battery cells that are completely free of the controversial heavy metal cobalt. This makes the novel battery cells more sustainable and around five percent cheaper than high-nickel cells with conventional NCM cell chemistry.

At the same time, SVOLT achieves an energy density with NMx that is comparable to that of NCM battery cells, while battery cell aging and product lifetime in use are significantly better.

With NMx, SVOLT offers a unique product that is more durable, less expensive and more sustainable than solutions available in the market today. In general, SVOLT focuses on the conscious consumer for whom sustainability is important.

SVOLT relies on a single crystal for its NMx battery cells. This minimizes one of the main causes of aging in e-vehicle batteries: the development of micro-cracks as well as fractures in the active cathode material and thus the wear of the cell.

As is also common with NCM cells, SVOLT also uses a coating ("nano-coating") only a few nanometers thick for its NMx battery cells, which protects the surface of the cathode material used from side reactions with the electrolyte and thus significantly slows down cycle aging as well as the calendar aging of the cells.

In addition, SVOLT relies on a complementary doping process ("doping") in which foreign atoms, the so-called doping material, are introduced into the cathode material. In this way, SVOLT not only succeeds in stabilizing NMx cells without cobalt, but also increases the overall safety compared to NCM811 cells.

Thanks to the complete elimination of the heavy metal cobalt, as well as a lowered nickel content, the NMx cells are not only much more sustainable, but also around five percent cheaper than classic high-nickel battery cells (NCM811). At the same time, the products achieve an energy density that is just under five percent lower than that of comparable NCM battery cells. This makes them particularly suitable for use in electric vehicles in the broad mid-range as well as upper-range market.

The NMx battery cell was first unveiled in September 2019 at the International Motor Show (IAA). After finalizing the cobalt-free cathode material in June 2019, SVOLT moved on to performance testing of the first prototype. Here, the focus was on optimizing the temperature curve as well as rigorous quality testing. The development project was completed in April 2020.

In January 2021, pilot production with 10 tons of cobalt-free cathode material was successfully completed at the battery cell factory in Changzhou, China. Annually, 5,000 tons of the central material for cobalt-free battery production are now produced in this cell factory in its current expansion stage.

From the second quarter of 2021, cobalt-free NMx battery cells with 115 Ah and an energy density of 245 Wh/kg will be available in an MEB format (33.4 x 220 x 102.5 mm). Their voltage is 3.74 V, and their capacity is 430 Wh. This gives the 115 Ah variant of the NMx battery an effective usable capacity of 396 Wh.

Also available for order is a cobalt-free cell variant with 226 Ah and an energy density of 240 Wh/kg, which is expected to be available from the fourth quarter of 2021. The 226 Ah version is SVOLT's proprietary L6 cell format (21.5 x 574 x 118 mm). The so-called L cells are long battery cells in a thin prismatic design with laterally positioned electrodes and degassing valves. Their voltage is 3.74 V, nominal energy 845 Wh.

Solid-state battery

SVOLT is making decisive progress in the development of solid-state batteries. The company recently produced its first batch of 20Ah cells with sulfide-based solid-state electrolyte. These solid-state cells are considered the next step in the development of advanced battery technology. SVOLT is the first battery manufacturer in China to demonstrate the production of this type of solid-state cell.

The SVOLT solid-state cells have an energy density of 350-400 Wh/kg. With this energy density, vehicles with a range of over 1,000 kilometers can be realized. The cells with sulfide-based solid-state electrolyte are superior to cells with liquid electrolyte in terms of energy density, charging speed, safety, cycling stability and temperature resistance. This was demonstrated by successfully completing abuse tests, such as a 200°C hot box test and a nail penetration test. These test conditions typically cause thermal runaway in high energy liquid electrolyte cells. SVOLT's new 20Ah cells, however, survived the tests without thermal runaway.

SVOLT employs its own research and development team to advance this important future technology. Together with top scientific institutes, the battery manufacturer is overcoming the technical challenges that still stand in the way of the solid-state battery's breakthrough: High conductivity of the solid-state electrolyte and separating layers, maintaining stable contact of the interfaces over long periods of time, and efficient transfer of lithium ions at the interface, even at high C rates.

SVOLT's Wuxi Lithium Battery Innovation Center and the Ningbo China Institute of Materials Technology and Engineering of the Chinese Academy of Sciences established a joint solid-state battery technology research center in April 2021. This has already filed 187 patents since then. SVOLT plans to further expand its R&D activities in the field of solid-state batteries as well as in new process technologies to further develop the technological basis for mass production.

SVOLT's R&D department has already filed several patents on solid-state batteries, including developing variants of hybrid electrolyte batteries.

In the next few years, they are planning a second and third generation of hybrid electrolytes with energy densities up to 350 Wh/kg and 750-800 Wh/L. Currently, the values are 250-300 Wh/kg and 550-650 Wh/L.

It is expected that SVOLT will have a solid-state battery with 450-500 Wh/kg in its portfolio in 2030.

Software + Cloud

In the future, vehicle manufacturers will be able to analyze data from vehicles with SVOLT technology via the "SVOLT Cloud Platform" and thus offer their customers additional services such as intelligent battery monitoring. To this end, SVOLT provides its customers with forecasting algorithms, which they can then integrate into their solutions as required and use for their services.

SVOLT began implementing the cloud and developing the corresponding algorithms back in 2018. Today, the company is using modern AI and machine learning methods alongside data from active e-vehicles from Great Wall Motor in real-world operations to continuously refine the algorithms.

The "SVOLT Cloud Platform" and its services are expected to be available to SVOLT's customers as early as two to four years from now. SVOLT is cooperating with Huawei and NIO to develop the cloud.

Privacy:

SVOLT does not have access to the "SVOLT Cloud Platform" or the data collected by the vehicle manufacturer, but merely provides its customers with the algorithmic intelligence required for its evaluation and interpretation.

If vehicle manufacturers provide SVOLT with the anonymized data from the vehicles, SVOLT can further improve the algorithmic intelligence of its solutions and thus develop even more efficient batteries and more sustainable solutions. The larger the data pool, the more tailored and optimized the cloud services will be for end users - for example, in the form of a charging cycle tailored to the personal driving style or a determination of the residual value of the battery.

Optimum energy efficiency is achieved when the longest possible range can be achieved with the least possible energy input. Here, too - as with the cooling issue - a consideration of the entire vehicle is crucial. This includes the powertrain, i.e. the efficiency of the power electronics and the electric motor, any heat losses, the aerodynamic properties of the vehicle, and the efficiency of the charging processes. To achieve an optimum result here, the battery should be kept in a "feel-good" state both thermally and electrically. Powerful control software can make a significant contribution to this through skillfully programmed algorithms. The deeper the understanding of the cell's active materials, the better the battery software is matched to it. As a result, the battery remains within its optimum operating window in terms of voltage and temperature at every load point. This not only has a positive impact on everyday driving performance, but also significantly increases the battery's service life.

Crash resistance

In reality, electric cars with batteries do not burn more often than vehicles with combustion engines.

But to avoid a vehicle fire, which starts at the cell level and in which a thermal event spreads from one battery cell to another, know-how is required along the entire product chain - from the cells to the modules to actively cooled high-voltage storage systems (packs).

The design of the individual components in particular plays a major role here. It is important to have comprehensive knowledge of the interactions between the battery, the battery system and the vehicle. SVOLT has the necessary systemic expertise and develops solutions that actively and passively counteract an e-vehicle fire. In addition, SVOLT's product portfolio includes battery solutions that cannot burn. Active vehicle safety and that of its occupants are paramount.

From a purely statistical point of view, electric cars do not catch fire more frequently than internal combustion vehicles. If an e-car fire does occur, the fire department has to proceed differently than when extinguishing a combustion engine: A fire lance is brought specifically up to the battery and the fire in the cells is fought directly by introducing water from the lance tip. The primary effect of this method is to cool the battery; oxygen is produced by the decomposition of the electrolyte and cannot be removed from the fire.

Crash resistance can be increased by mechanical measures, among other things. An impact can occur from the front, from behind, from the side or - in rare cases, for example due to a projectile - also from below. For all scenarios, it is crucial to sufficiently stiffen the body. This prevents intrusion into the interior of the lithium-ion cell, corresponding damage to the active material and thus a fire in the battery. Close cooperation between OEMs and battery manufacturers is therefore very important, especially on vehicle safety issues. At SVOLT, we practice a holistic approach here: we test the entire battery system at both cell and pack level, ensuring the highest level of safety and crash resistance.

Energy storage

SVOLT's Energy Storage Solutions (ESS) address utilities as well as industry, commerce and private households. The solutions are developed according to the latest design principles. The focus is on the attributes "safe", "strong" and "smart". Safety refers to the entire cell and the complete life cycle. In this respect, SVOLT ensures a continuous and smooth process - from production and delivery to operation and maintenance ("safe").

Technologies enable a wide range of intelligent functions

The design of the solution meets strict internal standards and the high quality requirements of the industry ("strong"). The complete lifecycle, including the management of large data volumes (big data), is mapped. This ensures all-round stable and reliable operation of the system. In addition, the solutions incorporate a range of smart technologies, including artificial intelligence (AI), which enable intelligent monitoring, early warning and prediction of potential faults. As a result, customers benefit from regional, collaborative control of the system as well as smart functions for control, operation and maintenance. This enables user companies to optimize their strategy in terms of both intelligent and flexible use and distribution of energy ("smart").

Roadmap for the availability of ESS systems

The provision of products, solutions and services around SVOLT's ESS follows a clear roadmap: So-called Energy Storage Units (ESU) will be available as early as this year, offering particularly high flexibility, scalability, intelligence, reliability, security and standardization. The CE-Series ESU, for example, is a highly modular and standardized energy storage solution based on LFP cell technology. It supports a wide variety of applications such as renewable energy integration, dynamic capacity expansion, demand-side energy management, distributed power generation, emergency power supply and rapid charging of electric vehicles. The solution features cells with 280 Ah and 3.2 V. In addition, medium-scale ESS systems are available to provide advanced thermal management and efficient temperature control in the cell. The CE-M-100/200 Medium-scale ESS solution features advanced fire protection mechanisms, ensuring safe and reliable operation over a long period of time. Modular liquid-cooled ESS components will then be launched in 2023. In the same year, SVOLT also plans to offer accompanying smart energy professional services.

In addition, SVOLT will offer a cloud-based Big Data service platform for regional energy supply. This promotes the use of renewable energies, increases flexibility as well as efficiency, and makes a decisive contribution to reducing pollutant emissions. Last but not least, this also supports the sustainable and ecologically oriented use of valuable energy resources.

5.Electromobility in general

Energy storage

The automotive industry's demand for batteries will grow enormously in the coming years. There are forecasts predicting a six-fold increase in demand for batteries by 2030. This demand will far exceed current global production capacities. That's why there are already more than 80 gigafactories being planned around the world.

Alongside digitization and autonomous driving, electromobility is one of the megatrends in the automotive industry. Due to the massive promotion of electromobility in many countries around the world in terms of passenger cars, commercial vehicles, buses and charging infrastructure, the trend will also continue and registration figures will rise. The more electric vehicles are needed, the more batteries are needed. In addition, the permissible emissions of internal combustion engines will be heavily regulated by EU standards in the coming years, so all car manufacturers in the EU will be active in electromobility accordingly. Nearly all established car manufacturers have recognized electromobility as the necessary strategic response to climate change.

According to EU estimates, production capacities of 400 GWh per year will be required in Europe by 2028. This corresponds to batteries for more than five million e-vehicles per year. The European Commission estimates that the number of electric vehicles will increase to between 50 and 200 million by 2028 and up to 900 million by 2040. By 2040, forecasts expect 900 million e-vehicles worldwide. This means that it will be some time before there is any talk of overcapacity. Currently, production will have to be increased significantly to meet demand.

SVOLT considers electromobility to be the technology currently ready for the market and available at mass-compatible prices to reduce fleet emissions and thus contribute to climate protection. This is helped by the fact that, according to the current state of the art, the overall efficiency (tank-to-wheel, TTW), which describes the energy chain of a vehicle from the point at which energy is taken in - at the charging station, for example - to the point at which it is discharged on the road, is far higher for today's e-car than for a hydrogen car. The total costs of hydrogen for the technology in the vehicle and for the necessary infrastructure are also significantly higher than for the e-car. The electricity consumption of hydrogen-powered cars is two and a half times higher than that of e-cars. Nevertheless, hydrogen is also a promising technology - for industrial use, for example. Incidentally, hydrogen-based drives also require a battery solution for use in the vehicle. Although this is smaller than in today's electric vehicles, it is nevertheless absolutely essential.

To further develop solid-state battery (SSB) technology, SVOLT has employed its own research and development team for several years. SVOLT's R&D department has already filed several patents on solid-state batteries, including variants of hybrid electrolyte batteries.

It is expected that SVOLT will have a 450-500 Wh/kg solid state battery in its portfolio by 2030.

6.Sustainability + Recycling

Sustainability

SVOLT attaches great importance to sustainable production processes and a transparent supply chain right through to the mine. Both production and the supply chain are set up according to international standards and are audited regularly.

In addition, SVOLT is working on sustainable concepts and solutions for the recycling of batteries and battery systems. The aim is to make sustainable, responsible use of natural resources and ensure a closed resource cycle.

In the future, all products in the European factories will be produced with 100 percent "green power". At the same time, the company is working on the further development of its production technologies and processes in order to constantly reduce the consumption of resources and materials.

SVOLT is also working on solutions to continuously reduce the CO2 footprint of production. This relates not only to production, but to the entire supply chain. Particular attention is paid here to the socially responsible awarding of contracts to raw material suppliers and the selection of European partners for the needs of its European factories.

The expectation of SVOLT's customers is that all industry stakeholders work together to reduce CO2 emissions along the entire vehicle production and value chains and ultimately achieve CO2 neutrality. As a battery manufacturer, SVOLT must make a significant contribution to this. In addition, a battery directive of the European Union is intended to gradually increase the recycling rate for batteries. Accordingly, a certain proportion of materials must come from recycling during production.

SVOLT not only focuses on producing ever more powerful, innovative, efficient and safe batteries for e-vehicles and energy storage, but equally strives for sustainable, transparent production processes - from the mine to the recycling of the battery systems.

Both production and supply chain at SVOLT are set up according to international standards and audited regularly. SVOLT not only attaches great importance to the transparency of procedures, the minimization of possible burdens and sustainable production processes, but above all to a transparent supply chain all the way to the mine.

In order to keep the CO2 footprint as low as possible, SVOLT generally follows a local-for-local approach. The aim here is to establish local supply chains and enable them to provide the required materials - where available. This also applies to the planned battery cell factories and high-voltage storage manufacturing facilities in Europe.

SVOLT attaches great importance to sustainable production processes and a transparent supply chain all the way to the mine. Thus, both production and the supply chain are set up according to international standards and are audited regularly.

In order to make raw material production and its supply chain as transparent as possible, SVOLT has already been investing specifically in lithium mining and ore processing with Pilbara Minerals (Australia) and Tianyuan New Energy Material (China) since 2017. Both companies - like all SVOLT suppliers - are regularly audited according to international standards (including OECD standards, which have been adopted by 38 member states).

The European Commission has drafted a proposal for a regulation on batteries and spent batteries (ongoing procedure 2020/0353/COD, source: https://eur-lex.europa.eu/procedure/DE/2020_353), which contains concrete recycling requirements. The draft stipulates that from 2025, cobalt, nickel and copper must be recycled at 90 percent, and lithium at 35 percent. The recycling efficiency for lithium-ion batteries is then to be 65 percent. Starting in 2030, recycling targets are to be increased: Cobalt, nickel and copper must then be recycled at 95 percent, and lithium at 70 percent, according to the draft. The recycling efficiency for lithium-ion batteries is then to be 70 percent.

The Commission's proposal also requires that, from January 1, 2027, information on the amount of recovered cobalt, lead, lithium or nickel in the active material contained in each battery model and batch must be provided. The amount of recovered active material in batteries is to be at least 16 percent cobalt, 85 percent lead, 6 percent lithium and 6 percent nickel beginning July 1, 2031. From July 1, 2036, the minimum content of recovered lithium and nickel is to increase to 12 percent, and that of cobalt to 26 percent.

The expectation of SVOLT's customers is that all industry stakeholders will work together to reduce CO2 emissions along the entire vehicle production and value chains and ultimately achieve CO2 neutrality. As a battery manufacturer, SVOLT must make a significant contribution to this. Thus, SVOLT constantly measures the emitted CO2 within production and supply chain and takes measures, also with suppliers, to come from approx. 150g CO2/Wh today to approx. 30g CO2/Wh in 2025/2026. To stop global warming, 0g CO2/Wh is SVOLT's target. The company is convinced that this will be achievable in the long term.

SVOLT takes a holistic approach, focusing on battery solutions that are as sustainable as currently technically possible. Examples include cobalt-free battery cells (NMX cells) and research into solid-state batteries.

In addition, SVOLT will power its factories with 100 percent green electricity. SVOLT also recently launched an initiative to reduce its carbon footprint throughout the battery lifecycle and meet sustainable industry requirements. It also aims to drive the use of recycled raw materials. SVOLT has set high goals to limit carbon dioxide emissions as well as become carbon neutral. This is to be achieved with measures across the entire supply chain, through increases in energy efficiency, the purchase or own generation of green electricity, sustainable construction and the recycling of raw materials.

With the in-house development of software solutions, SVOLT succeeds in determining residual values and thus optimally planning the reusability of batteries in Second Life and thus equipping Second Life solutions (for example energy storage solutions) in the best possible way.

SVOLT thinks beyond the "first life" of products in e-vehicles when it comes to batteries from the mine. The company is already developing solutions today to address issues that will become relevant in 2035, for example - battery recycling, for which there will be a market then.

For battery recycling, SVOLT has partnerships in Asia-Pacific. In Europe, the company is in the process of selecting a strategic partner to make recycling as successful as possible on a regional basis.

SVOLT are permanently working on solutions to continuously reduce the CO2 footprint of production. This refers not only to production, but to the entire supply chain. Particular attention is paid to socially responsible procurement of raw material suppliers and the selection of European partners for the needs of the European factories. In order to keep the CO2 footprint as low as possible, SVOLT pursues a local-for-local approach: The aim here is to establish local supply chains and enable them to provide the required materials - where available. This applies to all cell factories as well as module and pack manufacturing facilities in Europe.

Second life

The second life market is just emerging and will become particularly relevant when the first fully electric vehicles from the mass market end their life cycle. In addition, EU regulations also place demands on SVOLT, such as a quota for second-life applications. Furthermore, it will also be necessary from an economic point of view to recover raw materials in order to avoid a shortage of raw materials and to keep raw material prices low.

SVOLT estimates that second use cases will see a large market growth from around 2035 onwards and that a variety of storage solutions will then be offered on the market. The average lifetime of vehicles in Europe is currently 18 years, which means that not enough time has passed since the introduction of e-vehicles to have enough battery solutions for second life applications available at this point. Those who understand the residual value of batteries in their second lifecycle will have long-term success in this market. SVOLT therefore already offers cloud services and cloud battery management systems as a solution.

Recycling

SVOLT is currently working on the development of a comprehensive recycling concept with the aim of creating a closed material cycle. This includes products that have actually reached the end of their product life cycle and can also no longer be used in energy storage solutions, as well as the scrap generated in the production process. For example, the raw materials from the battery can be recovered in special processes so that these recycled metals can be used again as raw materials for battery production. SVOLT cooperates with external partners in the development of sustainable concepts and solutions for battery recycling. Sustainability as well as the minimization of the CO2 footprint are in the foreground for SVOLT.

SVOLT is currently working on the development of a comprehensive recycling concept. This includes products that have actually reached the end of their product life cycle and can also no longer be used in energy storage solutions, as well as the scrap generated in the production process. SVOLT's goal is to use battery systems as long and sustainably as possible. For this reason, SVOLT also offers energy storage solutions in which used battery systems are used. After all, if battery systems are no longer powerful enough for use in e-vehicles, they can often still be used in energy storage systems for several years without any problems in their so-called "second life". This includes power plant technology in the large, medium and small segments as well as wind and solar energy, but also off-grid systems and applications for the residential segment (e.g. in residential buildings).

In order to keep the CO2 footprint as low as possible, SVOLT generally follows a local-for-local approach. The aim is to establish and enable local supply chains and to provide the necessary materials where available. This applies to all cell factories as well as module and high-voltage storage manufacturing facilities in Europe. As the recycling concept has not yet been finalized, we are not yet providing more details on the possible cooperation partnerships.

Recycling in a battery factory falls into two broad categories: On the one hand, recycling within production is an important part of the sustainability concept that SVOLT pursues: Establishing the best possible material cycle is already incredibly important out of entrepreneurial self-interest, since the substances and materials used are expensive. Many materials are already recycled in the company's own production; for example, the coated electrode foils that are generated as rejects in the process are recycled and returned to the production cycle. There will therefore be no rejects or residual waste, let alone hazardous waste, at the sites in Saarland and Lauchhammer.

The second major part revolves around the recycling of finished batteries that have reached their "end of life". For this purpose, SVOLT is in talks with well-known German companies about cooperative ventures. A partnership with BASF has already been announced. Recycling quotas of 90 to 95 percent are very precisely specified by government, European and customer authorities. Basically, two types of recycling can be distinguished: On the one hand, there is the shredding of the components, which is carried out mechanically. On the other hand, there is the dissolving of the individual components in acids and bases to form the so-called "black mass". The recycling steps are a mixture of chemical and mechanical processes that require close monitoring, as the dissolution of the substances and materials is highly demanding. Such a chemical process will not take place in Überherrn and Heusweiler, as the legal restrictions at both sites are very tight.

7.SVOLT Saarland

General

In its search for a suitable location for its first European plants, SVOLT examined 32 sites across Europe in an intensive selection process between October 2019 and September 2020. Ultimately, the choice fell on Saarland.

As a modern industrial, logistics and innovation location, Saarland offers SVOLT the opportunity to acquire highly qualified employees. It is also characterized by a central location in the heart of the European economic area, an excellent infrastructure and a flourishing environment with internationally successful companies.

The "Linslerfeld" site in Überherrn was selected in particular in view of the size of the site, its availability, its infrastructural links and its optimized traffic situation with a direct link to the national road network.

The "Laminate Park" site in Heusweiler, in addition to the existing infrastructure already in industrial use and its proximity to the site of the future cell factory in Überherrn, was particularly convincing due to its good transport links. The site is directly connected to the B268 and the A8. In addition, there is a pedestrian connection to the Saarbahn station "Eiweiler Nord", which will enable employees and customers to get there easily even without a car.

The state-of-the-art cell factory will be expanded step by step and is expected to reach an installed production capacity of 6 GWh in the first phase, with 12 GWh held in reserve in terms of construction. In line with customer demand, SVOLT then plans to expand the production capacity by 6 GWh in each of the further construction phases, so that a total of 24 GWh can be industrialized at the site. This corresponds to batteries for 300,000 to 500,000 electric vehicles per year.

In Europe, SVOLT will focus on the development and production of subsystems such as battery cells and modules as well as their control systems.

The solutions planned for European customers include battery cells and modules in various cell formats and capacities as well as the assembly of high-voltage storage (pack) solutions.

SVOLT is in a regular and topic-related exchange with the responsible authorities in Saarland. In addition, we are always open to requests for dialog.

Jobs in Saarland

Production operations at SVOLT's planned high-voltage storage factory (Heusweiler plant) are similar to those of other automotive manufacturers and suppliers located in the region. Among other things, the production of battery modules and high-voltage storage units will require employees with skills in the following areas: Assembly, Process Development, Cell Technology, Maintenance, Logistics as well as Administration (Purchasing, Financial Accounting, Human Resources, Marketing, Sales, IT, Safeguarding and Testing). In the battery cell factory (Überherrn plant), additional employees are needed in the following areas: Electrochemistry, cell design, production planning, cell manufacturing, laboratory and testing.

At the two sites near Heusweiler and Überherrn, SVOLT is also planning to establish competence clusters in the areas of software, AI, process automation as well as process engineering - with the resulting need for personnel. Current job postings can be found here: https://SVOLT.jobs.personio.de/.

8.Location Überherrn

General

SVOLT has not expressed a preference for a location. Saarland applied to SVOLT for the "Linslerfeld" site. SVOLT merely stated the conditions and parameters for the potential site.

The Ministry of Economics has examined various areas as potential sites. Only the Ministry can provide further information on this. To our knowledge, however, there are no suitable alternative areas that can be qualified in the necessary time.

Procedure + expert opinion

The two-stage development plan procedure, which provides for early participation of the public and public interest groups, serves to create planning law as a basis for the construction of the project.

Comments can be submitted by all citizens as part of the two-stage land-use plan procedure, which also provides for early public participation. Citizens then have a legal right to have their objections examined and evaluated. As part of the procedure, citizens have a wide range of options for information and participation.

All expert opinions, results and conditions drawn up as part of the urban land use planning process will be publicly accessible. The first step, in terms of early participation of the public and public interest groups, was completed in July 2022.

The measurement and assessment of potential immissions are the subject of the commissioned expert reports. The effects on the uses requiring protection inside and outside the planning area are examined and, if necessary, conditions are imposed that must be complied with by SVOLT. At the current planning stage, the following expert opinions are planned for the maximum variant: Traffic noise expert opinion, plant noise expert opinion, climate expert opinion, air hygiene (traffic/plants), species protection expert opinion, biotope type mapping, green space plan, environmental assessment/environmental report according to BauGB, FFH compatibility assessment and landscape image analysis. As early as possible, the expert opinions will be published at the time the draft of the development plan is made available to the public. This means that legal and environmental requirements will be applied in full. Any environmental impacts caused by light, odors and pollutants will be reviewed, analyzed and assessed in the approval procedure in accordance with the Federal Immission Control Act (BImSchG).

Site

In addition to a functional arrangement and compact construction of the buildings in relation to each other, the conception of the factory layout focuses on minimizing the sealing of surfaces. At the same time, all areas that are not used for buildings, traffic and logistics are to be deliberately landscaped.

The aim is also to ensure that the future factory site blends harmoniously and sensibly into the surrounding landscape. To this end, an overall landscape planning concept will be drawn up in the course of the building construction planning, which will also provide for the planting of vegetation suitable for sound absorption in the spacing areas from the residential buildings. All prescribed distances, which are determined in the course of the approval procedure, will be observed. In addition, compensation areas will be created in the course of an impact compensation balancing.

In the conception of the layout of the SVOLT battery cell factory in Überherrn, the focus is not only on a functional arrangement and compact construction of the buildings in relation to each other, but also on minimizing land sealing.

In the planning, superfluous traffic areas are avoided on the entire site. At the same time, all areas that are not used for buildings, traffic and logistics are to be specifically landscaped. The aim is for the future factory site to blend harmoniously and sensibly into the surrounding landscape.

The green roofs and the water drainage system from SVOLT almost compensate for the surface sealing. Water is drained off via cisterns, so the roof water is not "lost" but can be put to good use.

In the course of planning the building construction, an overall landscape planning concept will be drawn up, which will also provide for the planting of vegetation suitable for sound absorption on the distance areas from the residential buildings. This will comply with all prescribed distances, which will be determined as part of the approval process.

SVOLT will endeavor to design the environmental areas as close to the natural environment of the Saarland as possible. On the one hand, these should be ecologically sensible, but on the other hand, they should also please the adjacent neighbors. This also includes that SVOLT and SHS plan to orient all utility buildings towards Friedrichweiler. This will serve to protect residents from noise. The park will also be built on this side of the site with natural privacy screening provided by the greenery. This will create additional distance from the company buildings.

All prescribed distances, which are determined within the framework of the approval procedures, are adhered to. SVOLT endeavors to work out a good and amicable solution, also for the local residents.

The TA Lärm (Technical Instructions on Noise) clearly regulates the distance to the nearest residential area, to which no factories may be built. Accordingly, no production buildings of any kind can be built closer than 500 meters to residential areas.

Energy + water

With a capacity of 12 GWh, energy consumption is currently assumed to be 410 GWh/year. This corresponds to around 66 percent of the originally assumed energy consumption. In the final expansion stage with a production capacity of 24 GWh, energy consumption is currently assumed to be 810 GWh/year (around 80 percent of the originally assumed electricity consumption). The final consumption figures will be submitted as part of the BImSchG procedure. The battery factory will be supplied via the existing overhead line as well as a transformer station, which will be newly erected in the course of the construction measures.

The plant will be supplied via the existing overhead line as well as a transformer station, which will be newly erected in the course of the construction work. Powering the production sites with green electricity is an essential part of SVOLT's European strategy.

SVOLT therefore plans to purchase 100 percent "green electricity" from the European central grid. In addition, SVOLT wants to focus on a direct feed-in concept so that as much directly generated electricity as possible from renewable sources is used without a detour via the central grid.

In addition, photovoltaic systems on the roofs of the factory buildings will also contribute to meeting the energy demand. According to current planning, around half of the roof areas of the planned battery factory are suitable for the installation of photovoltaic systems. For power supply at night or on days when solar radiation is insufficient, SVOLT plans to temporarily store the electricity generated in this way in energy storage solutions that SVOLT manufactures itself. The detailed planning also includes measures for combined heat and power generation and heat recovery from the exhaust air of the ventilation systems and heat-intensive production processes. The battery factory will be supplied with electricity via the existing overhead line and a new transformer station that will be built in the course of the construction work.

It is currently becoming apparent that the water consumption of the battery factory will be considerably lower than initially assumed: For example, a daily water consumption of 1,600 m3 is assumed for a capacity of 12 GWh, and a consumption of 2,770 m3/day in the final expansion stage with a capacity of 24 GWh. This corresponds to only a quarter of the originally assumed water volume. In addition, around 35 percent of this is earmarked as a safety reserve. This means that, as things stand at present, Stadtwerke Überherrn's capacities are sufficient for supply. In addition, a large part of the above-mentioned total water requirement can be covered by the use of service water and rainwater.

In order to further reduce the share of fresh water, SVOLT is planning a variety of measures. For example, fresh water consumption is to be significantly reduced through closed cycles, optimized cooling technology, and the use of industrial water and rainwater. For example, rainwater is to be specifically stored to supply the hydrants and WC flushes on the factory premises. In addition, the rainwater storage will be used to pre-cool the cooling water. SVOLT is also constantly working on the further development of production technologies and processes in order to reduce the consumption of resources and materials. To this end, SVOLT is developing, among other things, so-called dry coating systems. These significantly reduce the use of solvents and water consumption.

The "Feasibility and Demand Assessment of the Drinking Water Supply" in the context of the external development for the SVOLT settlement" by KDÜ (Kommunale Dienste Überherrn GmbH) as the supplier has also shown that the water demand formulated by SVOLT of just over 1 million m³ per year can be provided by KDÜ. At the same time, the drinking water supply in the community is ensured.

Even after realization of the final expansion of the battery cell factory, significant groundwater reserves still remain for public water supply.

The water consumptions mentioned in the feasibility and demand statements represent an upper limit. If SVOLT were to indicate to the utility a water demand in excess of this, it would first be necessary to determine whether this amount could be provided and, at the same time, to demonstrate that the public water supply would continue to be assured.

Environment + emissions

The measurement and assessment of potential immissions are the subject of the commissioned expert reports. In this context, effects on the uses requiring protection inside and outside the planning area will be examined and, if necessary, conditions will be imposed that must be complied with by SVOLT.

Any environmental impacts caused by light, odors and pollutants will be reviewed, analyzed and assessed in the approval procedure in accordance with the Federal Immission Control Act (BImSchG). The public will be informed publicly about the early participation opportunity for the settlement of SVOLT on the Linslerfeld in Überherrn in accordance with § 3 para. 1 BauGB (German Building Code) about expert opinions on this and other topics and will be given the opportunity to comment on and discuss topics concerning the settlement of SVOLT. Within the framework of public participation, comments can then be submitted by all citizens as part of the two-stage urban land use plan procedure.

According to the TA Luft, both the battery cell and the module and high-voltage storage factory must not emit any harmful air. Apart from lukewarm air (which will be between 18 and 19 degrees Celsius), and will come from the cooling towers, there will be no emissions at all.

Everything else will remain within the production process. Even the heat will be recycled by SVOLT. SVOLT basically sets the highest environmental standards for itself. In many cases, these are even higher than what is required by law. These include greening the biotopes in accordance with native flora and fauna, or installing a clever water management system on the roofs that combines both greening and photovoltaics, thereby saving energy.

SVOLT will also set the highest standards in terms of water. Cisterns will be installed for the surface water. The water that comes onto the site via the roofs will be purified via a receiving watercourse to clarify it in advance. Only then will it be released into the flood ditches, which are tributaries to the Saar River.

Emissions also include the issue of lighting: from SVOLT's point of view, 24-hour outdoor lighting makes no sense. SVOLT's principle is to use as little light as possible in the outdoor areas at night. Nevertheless, in order to implement the security concept for the plant in a meaningful way, SVOLT plans to work with motion detectors, radar and night vision cameras, among other things, to protect the perimeter. There will probably be dusk-to-dawn lighting at selected points on the plant site in the evenings, and the cycle path that will run past the plant site will also be illuminated for the safety of cyclists. There will be no lighting toward the adjacent forest to avoid disturbing nature and wildlife at night and attracting insects to the plant's air filtration systems.

Yes, this is possible. The "Linslerfeld" is located in a designated water protection area of zone 3. All conditions according to the protection area ordinance are fully complied with in order to exclude all hazards to the soil. Any environmental impacts due to light, odors and pollutants will be reviewed, analyzed and assessed in the approval procedure in accordance with BImSchG. SVOLT is already working closely with its local partners to adapt its standards to local requirements and conditions in the Saarland. This includes, among other things, the development and elaboration of fully comprehensive prevention concepts for wastewater and emission protection. Legal and environmental requirements will be applied in full.

The BauGB also provides for an environmental assessment as part of the urban land use plan procedure. In an environmental report, any impacts on nature and the landscape are first determined and, if ascertainable, intervention, avoidance and compensation regulations are made. At the present time, the project is not expected to have any significant negative impact on the climate, landscape or wildlife. The "Linslerfeld" is located in a designated water protection area of zone 3. All conditions according to the protection area ordinance are fully complied with in order to exclude all hazards to the soil.

Any environmental impacts due to light, odors and pollutants will be reviewed, analyzed and assessed in the approval procedure in accordance with BImSchG.

Safety

SVOLT will guarantee fire protection far beyond the legal requirements in the plant. To this end, SVOLT plans to draw up a fire protection plan, fire extinguishing plan and safety concept with the local fire department and all authorities. A guardhouse will be built at the plant itself and a plant fire department made up of company employees will be trained in double-digit numbers.

Traffic + logistics

In Überherrn, all traffic will be routed via the B269, thus avoiding frequentation of local areas. The use of prefabricated structures will speed up the construction process and reduce noise emissions.

In the course of the overall site development, it will be necessary to reroute the L168 state road to the north and south of the railroad embankment, as well as an alternative routing of the L279 state road. The rerouting of the L279 will be integrated into a landscaping concept. This will reduce the burden on Friedrichweiler caused by the road (currently around 500 cars/day).

In order to avoid frequenting the local areas, heavy goods traffic in particular is to be carried out exclusively via the B269. Truck waiting and retrieval areas are only planned on the plant site itself. For transport between the plants, SVOLT is currently examining the possibility of an electric, CO2-neutral truck shuttle service.

SVOLT is aware of a potential "wild parking" issue at other sites. This aspect of plant planning is therefore also taken into account in the layout design. In doing so, SVOLT is not only oriented towards the transport volume. Adequate parking facilities are also to be provided for delivery traffic.

SHS is currently working on the detailed concept: road planning including turning lanes, daily traffic volume, etc. is currently underway.

The site's complete road system will be designed to accommodate the targeted 2,000 employees. As with any factory, there will be some delivery and drop-off traffic bringing materials and driving finished products to customers.

Rail loading of products will also be very interesting, especially in Heusweiler. In the future, we will use electricity for shuttle traffic between the sites.

9.Location Heusweiler

The battery cells produced at other sites are further processed in Heusweiler. In this further processing, the battery cells are assembled into battery modules and connected to each other. Installed electronics monitor the individual cells. Several of these battery modules form the battery system (high-voltage storage / battery pack), which is installed in the vehicle as a closed overall system. In newer systems, the modules are sometimes omitted so that the battery cells are assembled directly into a battery pack (cell to pack).

The existing buildings in Heusweiler are currently being renovated and expanded in accordance with the plans relevant to SVOLT. In parallel, new buildings are being constructed on the site. Employees in Saarland have already moved into the renovated office building at the site in November 2022.

All demolition work in Heusweiler has been completed on schedule. The retrofitting measures in Heusweiler/Eiweiler are currently on schedule. From today's perspective, the economic situation and supply chain bottlenecks have no direct impact on the current construction measures from a time perspective due to advance planning and material stockpiling.

The centrally located building complex with production halls and a total area of 25,000 m2 will be retained and modernized in line with SVOLT's requirements. In the next step of the construction project, the space created will be built on with the planned extensions to the production and logistics halls.

The site was already acquired last year by a subsidiary of SHS Strukturholding Saar GmbH. All necessary construction measures will be carried out by SHS in coordination with SVOLT. SVOLT will lease the buildings and the site on a long-term basis for a minimum period of 15 years.

The whereabouts of the old hangar are currently the responsibility of SHS and are being clarified. SVOLT does not currently need the space for the conversion and operation of the module and high-voltage storage factory. If you have any further questions on this matter, we would like to refer you to the contact persons at SHS; we will be happy to put you in touch with them.

Both communities will benefit from the settlement of SVOLT through the trade tax. This is because, in the case of companies with several locations, the trade tax is divided proportionally among the location municipalities according to the respective payroll totals. In addition to the trade tax revenue, the region will also benefit from positive, secondary demand and employment effects.

As only handling and assembly processes are carried out in the module and pack factory, no increased noise or odor development is to be expected away from construction work and delivery traffic.

In addition to protecting the environment, SVOLT takes all necessary measures for fire protection. Since the existing infrastructure at the "Laminate Park" is a wood-processing plant, many of the necessary protective measures such as an infrastructure for a plant fire department, sprinkler systems in the buildings and storage tanks with extinguishing water are already available and will also be used by SVOLT after they have been modernized. All these measures are part of an overall concept for active fire prevention on the site.